For my Hong Kong internship this summer, I worked for Ann

Taylor Sourcing Far East Ltd. in the Ann Taylor Factory (ATF) and LOFT Outlet

(LOS) division. Specifically, I was on the merchandising team for woven styles

for ATF refined, ATF suits, ATF dresses, LOS refined and LOS dresses. The

refined lines include best selling styles from Ann Taylor and LOFT that have

been modified to 2nd tier quality to be sold at a lower price point.

There are no Ann Inc. stores in Asia, nor does Hong Kong have any in house

designers. All designs come from the design team in New York. The New York

office has the final say on everything from fabric approval, to color matching,

to trims. Because of this, we are in constant communication with our

counterparts in New York.

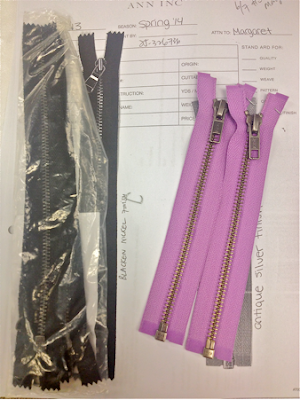

At the Hong Kong office, our main activities

can be broken down into development and production. Development involves fabric

sourcing, line building, ordering sample yardage, line review samples, trim sourcing,

and approving print or dye colors. Production activities include approving

trims and ordering them in bulk, the fitting process, bulk fabric testing,

garment production and shipping. Although development and production are two

distinct areas, it is difficult to separate the two because both occur

simultaneously. For example, while we may be ordering sample yardage for one style, we are

also getting zippers approved for another style. Even styles from the same line

can be at drastically different phases of completion. Throughout my internship,

I worked on the winter 2013 and spring 2014 lines.

My daily responsibilities involved uploading fabric

information sheets (FIS) and development test reports as they were completed. I

assisted in communications with textile mills, factories, and our counterparts

in New York. I placed orders for sample yardage and sent the color standards to

mills for them to match them as closely as possible. I requested cost information and lead times from factories to coordinate sample development and

delivery. When I communicated with New York, I asked them to place sample

requests and facilitated the shipment of trim samples and line review samples.

Fashion really is a global industry and I corresponded with people from New York, China, and Indonesia on a regular basis. Everyone in my office was constantly juggling multiple tasks and by the end, I had to prioritize my list of tasks based on the ever-looming deadlines, as well. I am so thankful for everything I have learned throughout this experience and I feel confident that fashion is the perfect industry for me. Despite the stress of deadlines, I tend to thrive under pressure. Most importantly, my career in fashion will always be filled with new and exciting challenges.

Fashion really is a global industry and I corresponded with people from New York, China, and Indonesia on a regular basis. Everyone in my office was constantly juggling multiple tasks and by the end, I had to prioritize my list of tasks based on the ever-looming deadlines, as well. I am so thankful for everything I have learned throughout this experience and I feel confident that fashion is the perfect industry for me. Despite the stress of deadlines, I tend to thrive under pressure. Most importantly, my career in fashion will always be filled with new and exciting challenges.

|

This fabric passed the initial inspection, but the factory

found a flaw during sample making. The slight skew of the pattern made it so

the pattern did not line up properly. In order for it to line up, the skirt

would pucker along the side seam. In this situation, the New York office must

choose whether to proceed anyway or to drop the style from the line.

Angelina DiFrancesco

Ann Taylor Sourcing Far East Ltd.

No comments:

Post a Comment